MARINE WORKSHOP FABRICATION

Precision Engineering by Bacviet Shiprepair Company

In the dynamic world of marine engineering, the reliability and performance of mechanical components play a crucial role in the safe and efficient operation of vessels and offshore systems. At Bacviet Shiprepair Company our dedicated marine workshop delivers specialized services in fabrication, reconditioning, and modification of mechanical and machinery parts, serving shipowners, fleet managers, and industrial clients across Vietnam and beyond.

.jpg)

Image for Marine Fabrication Workshop in Haiphong Vietnam

Precision Fabrication for Marine Machinery

Our workshop provides custom fabrication services for a wide range of mechanical components used in marine and offshore applications. With deep expertise and modern equipment, we manufacture parts that meet strict dimensional tolerances and material requirements, supporting both new installations and spare part needs.

We fabricate components such as:

- Shaft sleeves and bushings

- Pump casings and impellers

- Flanges, couplings, and adapters

- Engine supports and brackets

- Gearbox components and drive system parts

- Custom mechanical fittings for marine equipment

All fabricated parts are produced in accordance with international marine standards, using materials suitable for harsh offshore environments such as bronze, stainless steel, cast iron, and special alloys.

Reconditioning – Restoring Value to Worn Components

Instead of replacing worn-out parts, Bacviet Shiprepair Company offers a cost-effective alternative: reconditioning. This service involves restoring existing mechanical components to original specifications through machining, rebuilding, and precision finishing.

Our reconditioning services include:

- Bearing housing repair and resizing

- Shaft journal buildup and re-machining

- Pump impeller refurbishment

- Valve body and seat repair

- Surface treatment (metal spraying, grinding, polishing)

- Crack detection and repair (including dye penetrant and magnetic particle testing)

Reconditioned parts are tested and inspected to ensure reliability and extended service life, helping clients reduce downtime and save on costly imports or replacements.

Image recondition Windlass Shaft at Haiphong Vietnam

Modification for Operational Optimization

Marine systems often require modification to meet changing operational requirements or to adapt older systems to newer technologies.Bacviet Shiprepair’s workshop supports clients with tailored mechanical modifications that improve functionality, efficiency, or compliance.

Examples of our modification work:

- Altering mounting dimensions to match new equipment

- Modifying pump or motor housings to support retrofitted systems

- Adapting mechanical seals and couplings for improved performance

- Upgrading legacy parts to meet modern safety or efficiency standards

All modification projects are carried out with a combination of engineering consultation, reverse engineering (if drawings are unavailable), and precision machining.

Workshop Capabilities

Our workshop is fully equipped with a wide range of tools and machinery to ensure versatility, precision, and quality:

- CNC lathes and milling machines

- Vertical and horizontal boring machines

- Surface grinding and honing machines

- Dynamic balancing machines

- Hydraulic presses and keyway slotting tools

- TIG, MIG, and arc welding stations

- NDT and dimensional inspection equipment

We also offer reverse engineering services for obsolete or undocumented parts, using 3D scanning, measurement tools, and CAD modeling.

Experienced Team, Proven Quality

Bacviet Shiprepair Company's marine workshop is powered by a team of skilled technicians, machinists, and mechanical engineers with years of experience in marine systems. Our workflow is guided by strict quality control processes and documentation at every step — from material selection to final inspection.

We work closely with classification societies and client representatives to ensure compliance with standards such as:

- ABS, DNV, Lloyd’s Register

- ISO 9001 Quality Management

- Class-specific testing and certification

Our goal is to deliver high-quality, dependable components that meet both functional and safety requirements for marine operations.

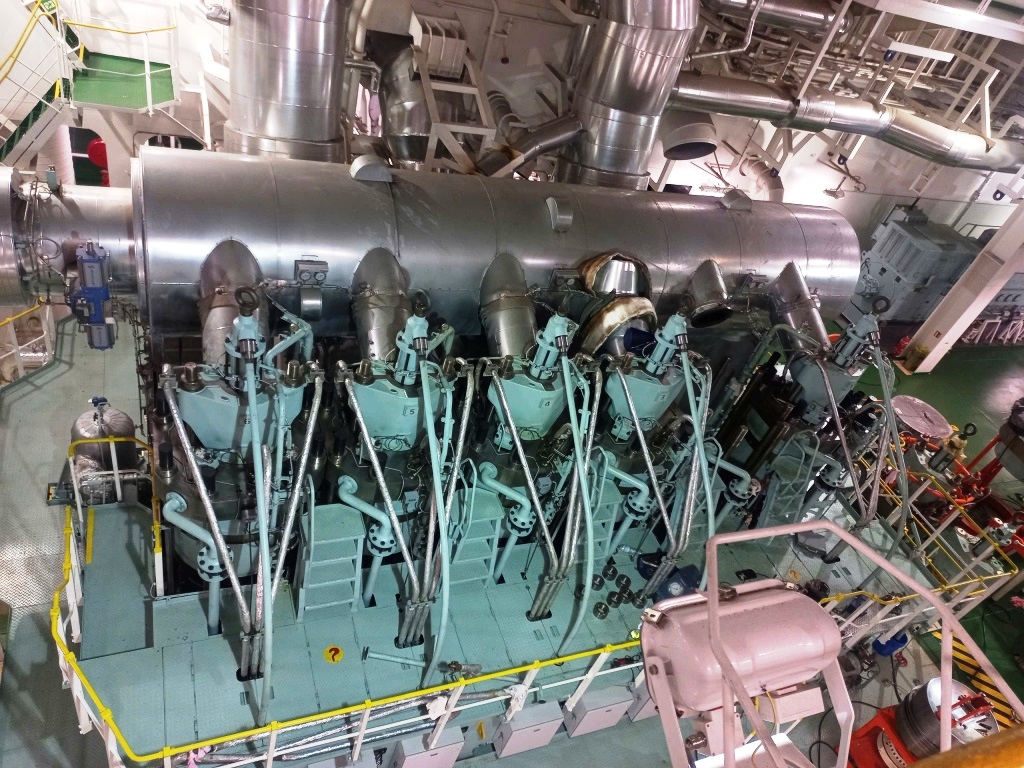

.jpg)

Image for recondition Main Engine Piston Crown at Workshop In Haiphong

Why Choose Bacviet Shiprepair's Marine Workshop?

- Specialized expertise in marine machinery and mechanical parts

- Complete solutions: fabrication, reconditioning, and modification under one roof

- Quick turnaround times to support urgent repair needs

- Custom-made parts even when original designs or spares are unavailable

- Cost-effective and sustainable alternative to full part replacements

- Located near Haiphong Port, ideal for local and international clients

Whether you need a new shaft coupling, reconditioned pump housing, or a modified gearbox mount, HASICO is ready to support your project with precision and reliability.

Get in Touch with Us

Bacviet Commercial and Shiptech Joint Stock Company

Add: 25/6/302 Vancao Street- Haian District - Haiphong City - Vietnam

Mobile/ WhatsApp/ WeChat: +84 904 125 520 (24/24); Fax: +84 2253 739 556

E-mail: bacviet@haiphongshiprepair.com; Website: haiphongshiprepair.com

PROJECTS UPDATE

- MAIN ENGINE WinGD 6X82-2.0 REPLACE CYLINDER LINER IN HAIPHONG VIETNAM Updated: 2025-04-21

- REPAIR ALUMINUM HYDRAULIC COOLER FOR SHIP CRANE IN VIETNAM Updated: 2025-04-21

- REPAIR HYDRAULIC CYLINDER FOR LIFEBOAT DAVIT OF MV JABAL SAMHAN IN PHU MY PORT, VIETNAM Updated: 2024-05-31

- WINDLASS, MOORING WINCH REPAIR IN VIETNAM Updated: 2024-04-23

VIDEO

- BAC VIET SHIPREPAIR COMPANY IN VIETNAM - INTRODUCE

- UNDERWATER HULL CLEANING BY ROV

- UNDERWATER SURVEY BY ROV IN VIETNAM

- LOAD TEST CONTAINER FLAT RACK IN VIETNAM

- CRANE JIB REPAIRS IN VIETNAM

- REPAIR PROPELLER IN VIETNAM

- STEEL REPAIRS IN VIETNAM

- STEEL REPAIRS IN VIETNAM

- TURBOCHARGER OVERHAULING IN VIETNAM

- STEEL REPAIRS IN VIETNAM

- REPAIR PROPELLER IN VIETNAM

- REWINDING GENERATOR, ELECTRIC MOTOR IN VIETNAM

- OVERHAUL MAIN ENGINE IN VIETNAM

- REPAIR CELL GUIDE IN VIETNAM

- REPAIR ALUMINUM ACCOMMODATION LADDER IN VIETNAM

- REPAIR JIB CRANE IN VIETNAM

- REPAIR JIB CRANE SHEAVE IN VIETNAM

- STEEL REPAIR FOR VESSEL IN VIETNAM

- LOAD TEST CRANE IN VIETNAM

- REPAIR ALUMINUM GANGWAY IN VIETNAM

- REPAIR ALUMINUM HYDRAULIC COOLER OF CRANE IN VIETNAM

- SHIP BRIDGE MAST MODIFICATION