Ferado - haiphong -phanh cac loai

Lượt xem: 4151 | Part of aux engine

Xuất sứ: CHINA

Nhà sản xuất: Mengzhou Qunli Friction Material Co., Ltd.

CÔNG TY BẮC VIỆT LÀ ĐẠI LÝ CHÍNH THỨC CỦA HÃNG MENGZHU QUNLI FRICTION MATERIAL Co., Ltd. CHUYÊN CUNG CẤP CÁC LOẠI FERADO HAIPHONG LÀM PHANH CHO CÁC THIẾT BỊ TÀU THỦY, CÔNG NGHIỆP TẠI THÌ TRƯỜNG VIỆT NAM

VỚI PHƯƠNG CHÂM:

- kHÁCH HÀNG LÀ TRUNG TÂM

- CHẤT LƯỢNG LÀ YẾU TỐ HÀNG ĐẦU

- GIÁ CẢ PHÙ HỢP

- ĐẢM BẢO THỜI GIAN GIAO HÀNG

CHÚNG TÔI CAM KẾT ĐÁP ỨNG TỐT NHẤT CÁC YÊU CẦU MÀ KHÁCH HÀNG ĐƯA RA

DOCKYARD IN VIETNAM

Your Trusted Partner in Dry Dock for your good Vesel in Vietnam

Located in the heart of Northern Vietnam’s maritime zone, Haiphong Shiprepair Company operates one of the most reliable and efficient dockyards for vessels in Vietnam. With over two decades of experience, a strategic location, and a skilled workforce, we provide comprehensive drydocking and afloat repair services to shipowners and operators around the world.

Whether your vessel needs routine maintenance, emergency repairs, or full overhauls, our dockyard is fully equipped to deliver solutions with speed, precision, and cost-efficiency.

Image of Pharung Shipyard in Haiphong Vietnam

Why Choose Vietnam for Your Docking Needs?

Vietnam has become a preferred destination for shipowners seeking high-quality repair and maintenance services at competitive costs. Here’s why:

- Strategic Location: Vietnam lies along major international shipping routes, making it a convenient stop for vessels operating in Southeast Asia, the Pacific, and beyond.

- Skilled Workforce: The country boasts a growing base of marine engineers, welders, electricians, and technicians trained to global standards.

- Cost-Effectiveness: Ship repair and drydocking in Vietnam offer significant savings compared to neighboring countries without compromising on quality.

- Growing Infrastructure: Vietnam is investing heavily in shipyard infrastructure, with Haiphong leading the way in Northern Vietnam.

Haiphong Shiprepair Company stands at the forefront of this transformation, offering world-class docking services to both domestic and international clients.

Our Dockyard Facilities

Our shipyard, located in Haiphong Port—the largest seaport in Northern Vietnam—features modern docking and repair facilities tailored to accommodate a wide range of vessel types and sizes.

Key Features:

- Graving Dock:

- Length: 180 meters

- Breadth: 25 meters

- Depth: 8 meters

- Capacity: Up to 25,000 DWT

- Berthing Facilities:

- Multiple repair berths with ample draft

- Equipped with cranes and power supply

- Workshops:

- Machining, mechanical, electrical, and welding shops

- CNC machines, dynamic balancing equipment, hydraulic test benches

- Mobile Teams:

- On-site repair teams ready to travel to other ports in Vietnam and Southeast Asia

Our facilities are designed to support fast, safe, and efficient repair operations, with round-the-clock support to minimize vessel downtime.

Image Vessel Bitumen Kakusho 3 in Drydock

LIST OF DOCKYARD IN VIETNAM

|

No |

Repair Yard |

No. |

Type |

Length(m) |

Width |

Capacity |

|

|

1 |

Bachdang Shipbuilding Industry Corporation Web Site: http://www.haiphongshiprepair.com Location: Haiphong city- north of VIET NAM |

1 |

Floating |

100 |

25 |

6,000 |

|

|

2 |

Pha Rung Shipyard Web Site: http://www.haiphongshiprepair.com Location: Haiphong City- North of VIET NAM |

1 |

Floating |

116 |

23 |

8,500 |

|

|

2 |

Dry |

160 |

25 |

16.000 |

|

||

|

3 |

BASON SHIPYARD Web Site: http://www.haiphongshiprepair.com Location: Ho Chi Minh City - South of VIET NAM |

1 |

Graving |

152 |

20 |

16,000 |

|

|

2 |

Floating |

160 |

23 |

8,500 |

|

||

|

4 |

SAIGON SHIPMARIN Web Site: http://www.haiphongshiprepair.com Location: Ho Chi Minh City - South of VIET NAM |

1 |

Floating |

150 |

29 |

10,000 |

|

|

2 |

Floating |

100 |

23 |

6,500 |

|

||

|

5 |

Hyundai Vinashin Web Site: http://www.haiphongshiprepair.com Location: Khanh Hoa province -Middle of VIET NAM |

1 |

Graving |

380 |

65 |

400,000 |

|

|

6 |

Namtrieu Vinashin Web Site: http://www.haiphongshiprepair.com Location: Haiphong City- North of VIET NAM |

1 |

Floating |

160 |

33 |

9,600 |

|

- Graving Dock:

- Length: 180 meters

- Breadth: 25 meters

- Depth: 8 meters

- Capacity: Up to 25,000 DWT

- Berthing Facilities:

- Multiple repair berths with ample draft

- Equipped with cranes and power supply

- Workshops:

- Machining, mechanical, electrical, and welding shops

- CNC machines, dynamic balancing equipment, hydraulic test benches

- Mobile Teams:

- On-site repair teams ready to travel to other ports in Vietnam and Southeast Asia

Our facilities are designed to support fast, safe, and efficient repair operations, with round-the-clock support to minimize vessel downtime.

Image Vessel He Cheng 3 at the Pier of Shipyard 2024

Contact us:

Bacviet Commercial and Shiptech Joint Stock Company

Add: 25/6/302 Vancao Street- Haian District - Haiphong City - Vietnam

Mobile/ WhatsApp/ WeChat: +84 904 125 520 (24/24); Fax: +84 2253 739 556

E-mail: bacviet@haiphongshiprepair.com; Website: haiphongshiprepair.com

VIDEO FOR MV MORGENSTOND I - IN DRYDOCK IN VIET NAM:

Welcome to Bacviet Commercial and Shiptech Joint Stock Company

Vietnam’s leading provider of ship repair, shipbuilding, and marine services. With over 20 years of experience, we deliver certified, cost-effective solutions to ensure your vessel’s safety, seaworthiness, and operational efficiency. Certified by Lloyd’s Register and Class NK, we serve ship owners, operators, and management companies at all ports and anchorages in Vietnam and select international ports.

Whether you need emergency repairs, load test deck crane services, annual services or spare parts supply, Bacviet is your trusted partner for long-term collaboration. Our 24/7/365 rapid response team, nationwide coverage, and global partnerships guarantee minimal downtime and maximum satisfaction.

for world-class maritime solutions.

Premier ship Premier ship repair services at Hai Phong Port - Copyright by Bacviet Shiptech

Premier ship Premier ship repair services at Hai Phong Port - Copyright by Bacviet Shiptech

Why Choose Bacviet?

Bacviet is the preferred choice for maritime services in Vietnam, offering unmatched expertise and reliability:

- Nationwide Coverage: We operate at all major ports and anchorages, from Hai Phong to Cai Mep.

- Certified Expertise: Approved by Lloyd’s Register (WPS/WPQ for Steel Plate Grade AH36) and Class NK (WPQ for steel plates and pipes).

- Experienced Team: Our engineers bring decades of expertise in ship repair and marine services.

- Global Reach: Partnerships with Combitrade (Germany), Palmarine (Hellas, Greece), and branches in Myanmar, Cambodia, and China.

- Trusted Partners: Collaborations with PIL Singapore, XT Ship Management (Israel),MSC SHIPMANAGEMENT LIMITED, V.Ships Offshore (Asia) Pte. Ltd.V. Ships Greece Ltd, Danaos Shipping Co. Ltd., Delta Corp Ship Management DMCCO, Norvice Shipping Asia PTE LTD

- Customer-Centric: We prioritize quality, timely delivery, and competitive pricing.

About Bacviet Shiptech

Founded in 2006 in Hai Phong City, Bacviet has grown into a maritime industry leader over the past two decades. Our state-of-the-art workshop supports fabrication, reconditioning, and outfitting for vessels of all types, including bulk carriers, oil tankers, and container ships. Our mission is to enhance vessel performance while ensuring safety, reliability, and sustainability through advanced technology and certified processes.

We are committed to customer satisfaction and sustainable growth, delivering solutions that meet international standards and exceed expectations. Bacviet is your one-stop partner for all maritime needs in Vietnam and beyond.

Advanced workshop for ship repair in Hai Phong - Copyright by Bacviet Shiptech

Our Comprehensive Services

Bacviet offers a full range of ship repair and marine services, tailored to your vessel’s requirements:

- Ship Repair:

- Structural repairs (steel, pipes, deck equipment like windlass and anchors).

- Machinery overhauls (engines, turbochargers, pumps, boilers).

- Hydraulic and electrical repairs (cranes, hatch covers, wiring, automation).

- Navigation and communication systems (radar, radio, VDR).

- Marine Services:

- Underwater services (inspections, hull cleaning, welding, propeller polishing).

- Load test deck crane using water bag technology.

- Tank and hold cleaning (fuel oil, ballast, cargo holds).

- Safety and compliance (FFE, LSA, VDR, GMDSS annual services).

- Supply and Fabrication:

- Spare parts, ship stores, bonded stores, and crane wire ropes.

- Steel and pipe fabrication for custom upgrades.

- Equipment reconditioning to OEM standards.

Certifications and Quality Assurance

Our services meet the highest international standards, backed by:

- Lloyd’s Register: WPS/WPQ for Steel Plate Grade AH36 (1G, 2G, 3G, 4G).

- Class NK: WPQ for steel plates (9.0mm to 36.0mm, 1G, 2G, 3G, 4G) and manual welding of steel pipes.

- Advanced Facilities: Our Hai Phong workshop is equipped for precision fabrication and reconditioning.

Where We Operate

Bacviet provides services at all major ports and anchorages in Vietnam, ensuring rapid response:

- Northern Vietnam: Hai Phong, Cai Lan, Lach Huyen, Nghi Son, Cam Pha, Hon La, and anchorages (Hon Gai, Cam Pha).

- Central Vietnam: Dung Quat, Quy Nhon, Van Phong, and anchorages (Vung Ang, Honnet).

- Southern Vietnam: Cai Mep, Phu My, Vung Tau, Saigon, Vinh Tan, Vissai, Thieng Lieng, Go Gia, and anchorages (Vung Tau).

- International Ports: Yangon (Myanmar), Sihanoukville (Cambodia), Fang Chang (China).

Our strategic logistics network ensures fast deployment to any location, minimizing downtime.

Also, we provide all kind services in some Anchorages of Vietnam as following.

Case Study: Emergency Repair at Vung Tau Anchorage

In January 2025, Bacviet completed an emergency underwater hull repair for a 60,000 DWT oil tanker at Vung Tau Anchorage. Our team deployed within 3 hours, performed underwater welding, and supplied critical spare parts, enabling the vessel to resume operations on schedule. This demonstrates our rapid response, technical expertise, and ability to handle complex repairs in challenging conditions.

Drydock Services in Vietnam- Copyright by Bacviet Shiptech

Trusted Global Partnerships

Bacviet collaborates with leading maritime organizations to deliver exceptional service:

Exclusive Agents:

- Combitrade (Germany): Supporting European clients.

- Palmarine (Hellas, Greece): Serving Mediterranean markets.

Major Partners:

- MSC SHIPMANAGEMENT LIMITED

- V.Ships Offshore (Asia) Pte. Ltd

- V. Ships Greece Ltd

- Danaos Shipping Co. Ltd.

- Delta Corp Ship Management DMCCO

- NORVIC SHIPPING ASIA PTE LTD

Port Authorities: Strong relationships with Vietnam’s key ports (Hai Phong, Cai Mep, Vung Tau).

Our Commitment to Excellence

Bacviet is driven by core principles:

- Customer Satisfaction: Tailored solutions with expert consultation.

- Uncompromising Quality: Services meeting international standards.

- Timely Delivery: Fast, efficient service to reduce downtime.

- Competitive Pricing: Cost-effective solutions for all clients.

- Sustainability: Eco-friendly methods for underwater works and waste management.

Contact Bacviet Today

Partner with Vietnam’s leading maritime service provider for reliable, cost-effective solutions:

- Mobile/WhatsApp/WeChat/Zalo: +84 904125520 (24/7/365)

- Email: bacviet@haiphongshiprepair.com

- Website: haiphongshiprepair.com

- Address: 25/6/302 Van Cao Street, Hai Phong City, Vietnam

VIDEO INTRODUCTION FOR SHIP REPAIR COMPANY IN VIETNAM - BACVIET COMMERCIAL AND SHIPTECH COMPANY

Air condition & refrigeration System

PLEASED CONTACT US TO RECEIVE GOOD SERVICES FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : 0084904125520; Email: bacviet@haiphongshiprepair.com

PLEASED CONTACT US TO RECEIVE GOOD SERVICES FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : 0084904125520; Email: bacviet@haiphongshiprepair.com

Bacviet Commercial and Shiptech company has been approved by Lloyd' Register for WPS up to Steel Plate Grade AH36 of Welding positions:1G, 2G, 3G and 4G ( Welding Procedure Specification) and WPQ Certificates 1G, 2G, 3G and 4G ( Welder Performance Qualification Certificates).

We also approved WPQ Certificates form Class NK (NK Register) for SW (Semi-automatic Welding) and Manual welding (MW) and TIG Welding (TW ).

We are leading company in Vietnam in repair services steel works for all type of Vessels in all Seaport and anchorage.

PLEASED CONTACT US TO RECEIVE GOOD SERVICES FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : 0084904125520; Email: bacviet@haiphongshiprepair.com

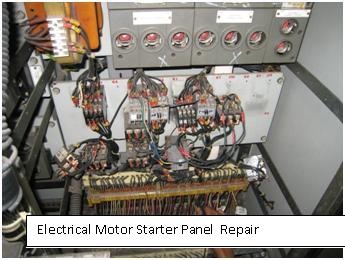

Bacviet Commercial and Shiptech is a leading company in repair services of Electriccal for all types of Vessel in Vietnam.

We can provide repair/ inspection ship electric system in/ at all the ports of Vietnam.

Our services as following:

- Rewinding electric motor

- Rewinding Generator

- Repair electric system

- Repair electric control system

- Repair electric board

- Repair Automatic control system .... etc

PLEASED TO CONTACT WITH US AS FOLLOWING:

BACVIET COMMERCIAL AND SHIPTECH JSC.

Address: 25/6/302 VanCao Street, Hai Phong City, Vietnam.

Tel: +84 904125 520 - Fax: +84.2253.739.556.

Email: bacviet@haiphongshiprepair.com; Website: http://haiphongshiprepair.com

Hydraulic Crane repair in Vietnam

With many experieces in this field and good skilled Hydraulic technicals of Makers: SMST, MACGREGOR, LIEBHERR, TTS, IHI .. We can carry out repair services all kind of hydraulic systems of the Cranes.

We have a Quick Team Mobilization and good skilled of Hydraulic systems, we provide full services for overhaul/ repair/ recondition/ maintainance Hydraulic Pumps, Hydraulic control valves, Hydraulic motors, Hydraulic piston and cylinders, repair/ aluminum welding Hydraulic cooller of Cranes in all the Ports of Vietnam.

PLEASED TO CONTACT WITH US AS FOLLOWING:

BACVIET COMMERCIAL AND SHIPTECH JSC

Address: 25/6/302 VanCao Street, Hai Phong City, Vietnam

Tel: +84 904125 520 - Fax: +84.2253.739.556

Email: bacviet@haiphongshiprepair.com; Website: http://haiphongshiprepair.com

Overhaul/ repair Marine Pump in Vietnam

PLEASED CONTACT US TO RECEIVE GOOD SERVICES FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : 0084904125520; Email: bacviet@haiphongshiprepair.com

With many experieces in this field, good skilled engineers, we cang arrange repair/ ouverhauling/ recondition for all kind of Marine Pumps in the Ports of Vietnam or at Vietnam Anchorage.

Overhaul/ maintainance for Pump with all types.

- Recondition for all parts of Pump (shaft, bearing, bushing, impeller, gear, screw, ...).

- Fabricate new parts of Pump (shaft, bearing, bushing, impeller, gear, screw, ...).

- Supply new parts of Pump (rollbearing, mechanical seal, ...).

PLEASED TO CONTACT WITH US AS FOLLOWING:

BACVIET COMMERCIAL AND SHIPTECH JSC

Address: 25/6/302 VanCao Street, Hai Phong City, Vietnam

Tel: +84 904125 520 - Fax: +84.2253.739.556

Email: bacviet@haiphongshiprepair.com; Website: http://haiphongshiprepair.com

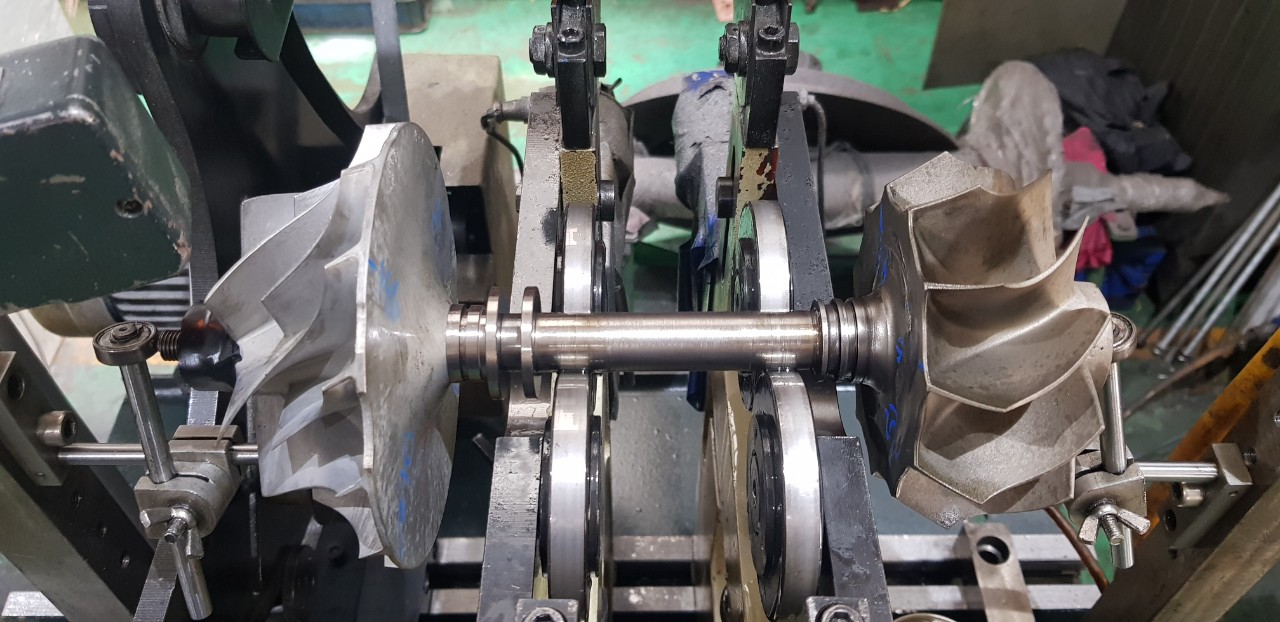

MAIN ENGINE TURBOCHARGE OVERHAULING IN VIETNAM

Overhaul Marine Turbocharger Services

Precision. Performance. Reliability.

At Haiphong Shiprepair Company, we understand that the marine turbocharger is the heart of a vessel’s engine efficiency. A properly functioning turbocharger ensures optimal engine performance, fuel economy, and compliance with emission standards. That’s why our Overhaul Marine Turbocharger services are designed to restore your equipment to peak condition, ensuring reliability and longevity even under the harshest marine environments.

Why Turbocharger Overhaul Matters

Marine turbochargers are subjected to extreme thermal and mechanical stress due to continuous operation. Over time, components wear down, build-ups occur, and performance drops. Without routine overhaul and maintenance, the turbocharger can fail—causing engine damage, increased fuel consumption, unplanned downtime, and costly repairs.

A professional turbocharger overhaul can:

-

Prevent unexpected breakdowns

-

Restore performance and fuel efficiency

-

Extend component lifespan

-

Ensure compliance with IMO emission regulations

-

Reduce long-term maintenance costs

Our overhaul service is not just maintenance—it’s a strategic investment in your ship’s performance.

Our Turbocharger Overhaul Capabilities

Haiphong Shiprepair Company offers complete overhaul services for all major makes and models of marine turbochargers, including but not limited to: ABB, MAN, Mitsubishi, Napier, KBB, and PBS.

Our overhaul process includes the following core stages:

1. Disassembly and Inspection

Upon receiving the turbocharger or accessing it onboard, our certified technicians begin with careful disassembly. Each component is examined for signs of wear, corrosion, imbalance, or damage.

-

Rotor shaft inspection and run-out measurement

-

Bearing and seal condition check

-

Casing and nozzle ring examination for erosion or cracking

-

Visual and dimensional analysis of turbine and compressor wheels

We prepare a detailed inspection report with photos and recommendations, which is shared with the client for transparency and decision-making.

2. Cleaning and Restoration

All parts are thoroughly cleaned using specialized equipment such as ultrasonic baths, chemical cleaning, and blasting machines.

-

Removal of carbon deposits and oil residues

-

Surface treatment to prevent future corrosion

-

Precision balancing of rotating parts

-

Reconditioning or replacement of worn components as per OEM standards

When necessary, we machine or replace parts to ensure the turbocharger meets exact tolerances and performance specifications.

.jpg)

Image for Dynamic Balancing Turbocharger VTR 454 -32

3. Reassembly and Testing

Using high-quality parts and OEM guidelines, our technicians carefully reassemble the turbocharger under strict quality controls.

-

Dynamic balancing of the rotor assembly

-

Measurement of axial and radial clearances

-

Air and oil leak tests

-

Trial runs and performance verification (where applicable)

We maintain detailed records of every overhaul, ensuring traceability and compliance with class and regulatory requirements.

Image Dynamic Balancing Turbocharge

Onboard and Workshop Services

We offer both onboard and workshop-based turbocharger overhaul services, depending on the situation and customer preference.

-

Onboard Services: Our mobile teams are available 24/7 for emergency repairs and planned overhauls at ports across Vietnam and Southeast Asia.

-

Workshop Overhauls: For comprehensive servicing, we offer fully equipped facilities at our Haiphong base, with modern tools, lifting systems, and test benches.

Regardless of location, our engineers ensure consistent service quality and adherence to safety standards.

Certified and Trusted Expertise

Haiphong Shiprepair Company employs a team of highly trained and certified engineers who bring decades of combined experience in marine engine systems. We follow strict international standards and are approved by leading classification societies such as DNV, BV, LR, and ABS.

With in-depth knowledge of turbocharger technology and direct access to OEM documentation and spares, we ensure your turbocharger is restored to “as-new” condition—or better.

Spare Parts Supply

We maintain a strong supply chain and inventory of genuine and high-quality spare parts for all major turbocharger brands. Whether you need a replacement rotor, bearing housing, or a complete cartridge unit, we deliver fast and reliably, minimizing your vessel’s downtime.

Why Choose Haiphong Shiprepair?

-

Strategic Location: Situated in Northern Vietnam's maritime hub, we’re ideally positioned to serve ships transiting the region.

-

Comprehensive Marine Services: Turbocharger overhaul is just one of our many core services, including engine repair, hull treatment, mechanical fabrication, and electrical systems.

-

Fast Turnaround: We understand vessel schedules are tight. Our teams work around the clock to minimize turnaround time without compromising on quality.

-

Customer-Focused: We build long-term relationships through reliability, transparency, and customized support.

Contact Us

Need urgent turbocharger assistance or planning your next overhaul? Contact our team today to learn more about how Haiphong Shiprepair Company can help.

Email: bacviet@haiphongshiprepair.com

Mobile/ WhatsApp/ WeChat/ Zalo: +84 904125520 ( 24/7)

Website: www.haiphongshiprepair.com

Haiphong Shiprepair Company — Your trusted partner for dependable marine turbocharger overhaul services.

Keep your engines running. Keep your voyages smooth.

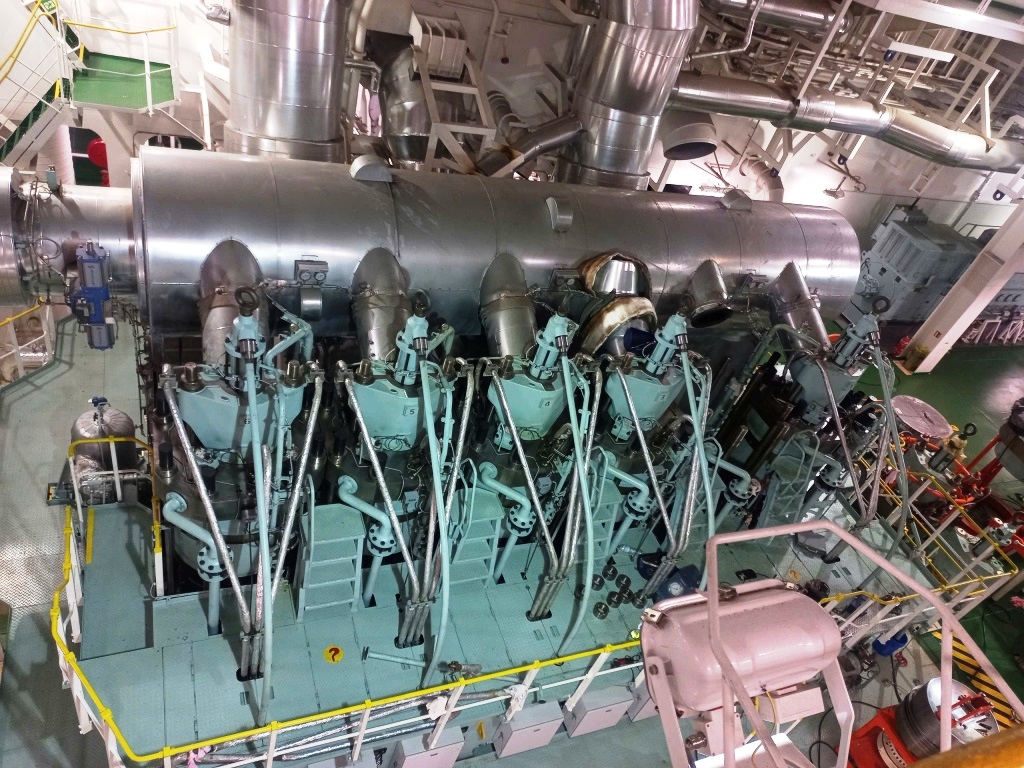

Repair services Main Engine & aux engine in Vietnam

PLEASED CONTACT US TO RECEIVE GOOD SERVICES FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : 0084904125520; Email: bacviet@haiphongshiprepair.com

Bacviet Commercial and Shiptech company supplies repair services, overhauling services etc for Main Engine and Generator Engine of Ship in Vietnam

We have a Quick Team Mobilization and good skilled engineers of Marine Engine, we provide full services for overhaul/ repair/ recondition/ maintainance Main Engine and Generator Engine in all the Ports of Vietnam.

Our objectives are:

+ Satisfy all requests of the customers and customer's satisfaction is key for the sustainable development of the Company

+ Quality of products and services are of essence

+ Ensuring timely handover of products as promised

+ Reasonable prices

We provide repair services for Main Engine and Generator Engine of vessel in all the Ports of Vietnam as following:

Overhaul Main Engine and Generator Engine in Cam pha Port, overhaul Main Engine and Generator Engine in Ha long Port, overhaul Main Engine and Generator Engine in Hon gai Port, overhaul Main Engine and Generator Engine in Lach huyen Port, overhaul Main Engine and Generator Engine in Cai lan Port, overhaul Main Engine and Generator Engine in Nghi son Port, overhaul Main Engine and Generator Engine in Hai phongPort, overhaul Main Engine and Generator Engine in Cua lo Port, overhaul Main Engine and Generator Engine in Son Duong Port; overhaul Main Engine and Generator Engine in Dung quat Port; overhaul Main Engine and Generator Engine in Phu my Port, overhaul Main Engine and Generator Engine in Cai mep Port; overhaul Main Engine and Generator Engine in Port of HCM City.

Also you can find our services for overhaul Main Engine and Generator Engine in Foreign Ports as Cambodia, Myanmar as below:

- Overhaul Main Engine and Generator Engine in Shihanoukville Port of Cambodia.

- Overhaul Main Engine and Generator Engine in Yangon Port of Myanmar.

PLEASED TO CONTACT WITH US AS FOLLOWING:

BACVIET COMMERCIAL AND SHIPTECH JSC.

Address: 25/6/302 VanCao Street, Hai Phong City, Vietnam.

Tel: +84 904125 520 - Fax: +84.2253.739.556.

Email: bacviet@haiphongshiprepair.com; Website: http://haiphongshiprepair.com

.jpg)

.jpg)

Reliable Ship Repair in Vietnam – Serving All Major Ports

When it comes to professional ship repair in Vietnam, Bacviet Commercial and Shiptech Company is a name trusted by shipowners, managers, and marine operators across the globe. Headquartered in Hai Phong, our company delivers a full spectrum of ship repair and marine engineering services, covering all major ports and anchorages in Vietnam.

With over 20 years of industry experience, we provide timely and cost-effective ship repair services, helping clients reduce downtime and maintain vessel performance. From emergency repairs in Hai Phong to routine maintenance in Vung Tau, Da Nang, or Ho Chi Minh City, our skilled engineers and technicians are ready 24/7 to mobilize and support vessels of all sizes.

Main Engine in Ship - Ship repair in Vietnam.

Our Core Marine Services

Bacviet Commercial and Shiptech Company has a team of professionally trained engineers and has many years of operation in the field of ship repair in Vietnam. We are confident that the products and services we provide are always on schedule and of the best quality in all conditions.

Main products for “Ship Repair in Vietnam” which are supplied as the best from Bacviet Commercial and Shiptech Company such as:

- Main Engine & aux engine, - Turbocharger overhauling, - Pumps repair, - Hydraulic crane, - Electrical repair works, - Steel repairs works

- Tail Shaft and Propeller, - Machinery parts recondition, - Air condition & refrigeration System, - Recondition Piston Crown & Exhaust Valves... etc.

In addition, we provide Marine services, Ship spare parts, Internal Audit ISM, ISPS, MLC, Dockyard Services, Underwater services for the ship in all the ports and anchorages in Viet Nam

Bacviet Commercial and Shiptech Company - Ship repair in Vietnam.

We offer complete ship repair and maintenance services in Vietnam, including:

- Hull and Steel Repairs: Welding, steel plate renewal, and structure restoration.

- Mechanical and Engine Overhaul: Main engine and auxiliary engine servicing, turbocharger cleaning, pump repair, etc.

- Electrical and Automation Systems: Troubleshooting navigation equipment, automation controls, and generator systems.

- Underwater Services: Hull cleaning, propeller polishing, in-water surveys, and underwater welding, performed by certified divers.

- Safety Equipment Servicing: Inspection and certification of firefighting systems (CO₂, foam, dry powder), lifeboats, and life rafts.

- Marine Supply Services: Spare parts, lubricants, fresh water, and provisions delivered directly onboard.

Our services are tailored to meet international standards and Class Society regulations (DNV, ABS, BV, LR, NK, etc.).

You will be served by us in all regions of Vietnam as soon as you need.

Up to present time, we have done more than 8,000 (Eight thousand) projects for about 6,000 (Six thousand) Foreign Vessels and Domestic Vessels at the Ports and Anchorages of Vietnam.

With the strength of coverage throughout Vietnam, we are confident that we can quickly be on ship and supply all services for you when you need it at all ports of Vietnam as following:

- Ship repair in Hai Phong Port, Vietnam.

- Ship repair in Cai Lan Port, Vietnam.

- Ship repair in Lach Huyen Port - HITC, Vietnam.

- Ship repair in Son Duong Port, Vietnam.

- Ship repair in Phu My Port, Vietnam.

- Ship repair in Cai Mep Port, Vietnam.

- Ship repair in Quy Nhon Port, Vietnam.

- Ship repair in Ho Chi Minh City, Vietnam.

- Ship repair in Dung Quat Port, Vietnam.

- Ship repair in Van Phong Port, Vietnam.

- Ship repair in Vinh Tan Port, Vietnam.

- Ship repair in Hon La Port, Vietnam.

- Ship repair in Vissai Port, Vietnam.

- Ship repair in Nghi Son Port, Vietnam.

- Ship repair in Cam Pha Port, Vietnam.

- Ship repair in Thieng Lieng Port, Vietnam.

- Ship repair Go Gia Port, Vietnam.

Lach Huyen Port - HITC, Vietnam.

And we also provide ship repair services at anchorages in Vietnam as following ( VIETNAM PORT AND ANCHORAGE):

- Ship Repair in Hon gai anchorage.

- Ship repair in Vung tau anchorage.

- Ship Repair in Cam pha anchorage.

- Ship Repair in Ha long anchorage.

- Ship Repair Cua Lo anchorage.

- Ship Repair Vung Ang anchorage.

- Ship Repair Nghi son anchorage.

- Ship Repair Honnet anchorage.

Strategic Advantage in Hai Phong

As our home base, Hai Phong shipyard is equipped with advanced tools and facilities to handle both afloat and dry-dock repairs. The city’s central location on Vietnam’s northern coast makes it a critical hub for vessels operating along regional trade routes and international shipping lanes.

Why Choose Bacviet Commercial and Shiptech Company?

+ Nationwide Coverage: Ship repair teams available in every key ports and anchorages in Vietnam.

+ 24/7 Availability: Emergency ship repair services anytime, anywhere.

+ Experienced Engineers: Certified technicians with global vessel experience.

+Competitive Rates: Transparent pricing and flexible service packages.

+Strong Logistics Support: Fast access to spare parts and marine supplies.

Serving All Vessel Types

We serve a wide range of vessels, including:

+ General cargo ships, + Bulk carriers, + Container ships, + Oil tankers, + LNG carriers, + Offshore support vessels (OSVs).

+ Tugboats and barges

To matter your vessel type or location, Bacviet Commercial and Shiptech Company is committed to ensuring your ship returns to operation safely and efficiently.

Contact Us Today

If you're looking for trusted ship repair services in Vietnam, we're here to help. Reach out to us for immediate assistance or to schedule services at your next port of call.

Bacviet Commercial and Shiptech Joint Stock Company

Add: 25/6/302 Vancao Street- Haian District - Haiphong City - Vietnam

Mobile/ WhatsApp/ WeChat: +84 904 125 520 (24/24); Fax: +84 2253 739 556

E-mail: bacviet@haiphongshiprepair.com; Website: haiphongshiprepair.com

Bacviet Commercial and Shiptech Company is always the best choice when you need ship repair in Vietnam. Please put your trust in us and let us provide the best ship repair in Vietnam to you.

VIDEO CLIP FOR RECONDITION PISTON CROWN AND EXHAUST SPINDLE FOR MAIN ENGINE MAN B&W 12K 98MC

Tail Shaft and Propeller

WE PROVIDE MANY BEST SHIP SERVICE IN VIETNAM

PLEASED CONTACT US TO RECEIVE GOOD SERVICES FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : 0084904125520; Email: bacviet@haiphongshiprepair.com

Bacviet Commercial and Shiptech is a leading company in ship services of ship in all seaports or offshore in Vietnam. With many years experience in Ship management, Ship repair, marine services and also there are many good skilled technicals, quick team mobilization. We always give customers the absolute trusted, smooth jobs, fast time to complete jobs and good prices for all kinds of orders.

We have approved by IACS such as Class NK, BV, ABS, LR, DNV - LR in the fields as following:

1/ Underwater works in Vietnam:

- Underwater hull inspection UWI.

- Underwater inspection lieu dock UWILD Class survey.

- Underwater hull cleaning.

- Underwater Anodes installing.

- Underwater Sealing of leakage.

- Underwater cofferdam installation.

- Underwater blanking and plugging.

- Underwater polishing propeller.

- Underwater cutting rope.

- Underwater repair propeller blade damage.

- Underwater welding.

2/ FFE & LSA: Fire Fighting Equipments and Life Saving Appliances:

- Annual Inspection, Survey and Certification of Life-Saving Appliances.

- Annual Inspection, Survey and Certification of Fire-Fighting Equipment.

- Annual and five-yearly service of lifeboats, rescue boats, davits, winches, hook release mechanisms

- Supply spare parts.

3/ Lifting Gear Services in Vietnam:

- Inspect Lifting Gear for Crane/ Derricks ⇒ VIDEO CLIP HERE

- Inspect deck and mooring gears.

- Inspect Gangway gears.

- Load test Crane/ Derricks.

- Load test mooring gears.

- Load test Gangway/ accommodation ladder.

4/ Servicing for Navigation equipments:

- Repair services/ annual services Gyro Compass in Vietnam.

- Repair services/ annual services GMDSS in Vietnam.

- Repair services/ annual services Rada in Vietnam.

- Repair services/ annual services Auto Pilot in Vietnam.

- Repair services/ annual services Automatic Tracking Aid in Vietnam.

- Repair services/ annual services ARPAP in Vietnam.

- Repair services/ annual services Speed & Distance Log Device in Vietnam.

- Repair services/ annual services Echo Sounder in Vietnam.

- Repair services/ annual services Electronic Chart Display Information System ECDIS in Vietnam.

- Repair services/ annual services Automatic Identification System AIS in Vietnam.

- Repair services/ annual services Long Range Tracking and Identification (LRIT) System in Vietnam.

- Repair services/ annual services Rudder Angle Indicator in Vietnam.

- Repair services/ annual services Voyage Data Recorder VDR in Vietnam.

- Repair services/ annual services Rate of turn indicator in Vietnam.

- Repair services/ annual services GPS Receiver in Vietnam.

- Repair services/ annual services Sound Reception System in Vietnam.

- Repair services/ annual services Navigational Lights in Vietnam.

- Repair services/ annual services Ship Whistle in Vietnam.

- Repair services/ annual services Daylight Signalling Lamp in Vietnam.

- Repair services/ annual services Pilot Card in Vietnam.

- Repair services/ annual services Transmitting Heading Devise in Vietnam.

Contact us:

Bacviet Commercial and Shiptech Joint Stock Company

Add: 25/6/302 Vancao Street- Haian District - Haiphong City - Vietnam

Mobile/ WhatsApp/ WeChat: +84 904 125 520 (24/24); Fax: +84 2253 739 556

E-mail: bacviet@haiphongshiprepair.com; Website: haiphongshiprepair.com

MARINE WORKSHOP FABRICATION

Precision Engineering by Bacviet Shiprepair Company

In the dynamic world of marine engineering, the reliability and performance of mechanical components play a crucial role in the safe and efficient operation of vessels and offshore systems. At Bacviet Shiprepair Company our dedicated marine workshop delivers specialized services in fabrication, reconditioning, and modification of mechanical and machinery parts, serving shipowners, fleet managers, and industrial clients across Vietnam and beyond.

.jpg)

Image for Marine Fabrication Workshop in Haiphong Vietnam

Precision Fabrication for Marine Machinery

Our workshop provides custom fabrication services for a wide range of mechanical components used in marine and offshore applications. With deep expertise and modern equipment, we manufacture parts that meet strict dimensional tolerances and material requirements, supporting both new installations and spare part needs.

We fabricate components such as:

- Shaft sleeves and bushings

- Pump casings and impellers

- Flanges, couplings, and adapters

- Engine supports and brackets

- Gearbox components and drive system parts

- Custom mechanical fittings for marine equipment

All fabricated parts are produced in accordance with international marine standards, using materials suitable for harsh offshore environments such as bronze, stainless steel, cast iron, and special alloys.

Reconditioning – Restoring Value to Worn Components

Instead of replacing worn-out parts, Bacviet Shiprepair Company offers a cost-effective alternative: reconditioning. This service involves restoring existing mechanical components to original specifications through machining, rebuilding, and precision finishing.

Our reconditioning services include:

- Bearing housing repair and resizing

- Shaft journal buildup and re-machining

- Pump impeller refurbishment

- Valve body and seat repair

- Surface treatment (metal spraying, grinding, polishing)

- Crack detection and repair (including dye penetrant and magnetic particle testing)

Reconditioned parts are tested and inspected to ensure reliability and extended service life, helping clients reduce downtime and save on costly imports or replacements.

Image recondition Windlass Shaft at Haiphong Vietnam

Modification for Operational Optimization

Marine systems often require modification to meet changing operational requirements or to adapt older systems to newer technologies.Bacviet Shiprepair’s workshop supports clients with tailored mechanical modifications that improve functionality, efficiency, or compliance.

Examples of our modification work:

- Altering mounting dimensions to match new equipment

- Modifying pump or motor housings to support retrofitted systems

- Adapting mechanical seals and couplings for improved performance

- Upgrading legacy parts to meet modern safety or efficiency standards

All modification projects are carried out with a combination of engineering consultation, reverse engineering (if drawings are unavailable), and precision machining.

Workshop Capabilities

Our workshop is fully equipped with a wide range of tools and machinery to ensure versatility, precision, and quality:

- CNC lathes and milling machines

- Vertical and horizontal boring machines

- Surface grinding and honing machines

- Dynamic balancing machines

- Hydraulic presses and keyway slotting tools

- TIG, MIG, and arc welding stations

- NDT and dimensional inspection equipment

We also offer reverse engineering services for obsolete or undocumented parts, using 3D scanning, measurement tools, and CAD modeling.

Experienced Team, Proven Quality

Bacviet Shiprepair Company's marine workshop is powered by a team of skilled technicians, machinists, and mechanical engineers with years of experience in marine systems. Our workflow is guided by strict quality control processes and documentation at every step — from material selection to final inspection.

We work closely with classification societies and client representatives to ensure compliance with standards such as:

- ABS, DNV, Lloyd’s Register

- ISO 9001 Quality Management

- Class-specific testing and certification

Our goal is to deliver high-quality, dependable components that meet both functional and safety requirements for marine operations.

.jpg)

Image for recondition Main Engine Piston Crown at Workshop In Haiphong

Why Choose Bacviet Shiprepair's Marine Workshop?

- Specialized expertise in marine machinery and mechanical parts

- Complete solutions: fabrication, reconditioning, and modification under one roof

- Quick turnaround times to support urgent repair needs

- Custom-made parts even when original designs or spares are unavailable

- Cost-effective and sustainable alternative to full part replacements

- Located near Haiphong Port, ideal for local and international clients

Whether you need a new shaft coupling, reconditioned pump housing, or a modified gearbox mount, HASICO is ready to support your project with precision and reliability.

Get in Touch with Us

Bacviet Commercial and Shiptech Joint Stock Company

Add: 25/6/302 Vancao Street- Haian District - Haiphong City - Vietnam

Mobile/ WhatsApp/ WeChat: +84 904 125 520 (24/24); Fax: +84 2253 739 556

E-mail: bacviet@haiphongshiprepair.com; Website: haiphongshiprepair.com

SHIP SUPPLY IN VIETNAM

PLEASED CONTACT US TO RECEIVE GOOD SERVICES FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : 0084904125520; Email: bacviet@haiphongshiprepair.com

Bacviet Commercial and Shiptech is a leading company to supplies spare parts, material Cabin Store, Deck stores Electrical stores Engine stores...etc. Our produst to be delivered on board in all the Sea Ports of Vietnam with:

- Quality of products and services are the essence

- Ensuring timely handover of products as promised

- Reasonable prices

Main products to be supplied:

- Provison

- Bonded Sores.

- Cabin Stores.

- Nautical Charts.

- Medical Supplies.

- Deck Stores.

- Cabin Stores.

- Engine Stores.

- Safety Equipments.

- Electrical Stores.

- Navigation spare parts.

Contact us:

Bacviet Commercial and Shiptech Joint Stock Company

Add: 25/6/302 Vancao Street- Haian District - Haiphong City - Vietnam

Mobile/ WhatsApp/ WeChat: +84 904 125 520 (24/24); Fax: +84 2253 739 556

E-mail: bacviet@haiphongshiprepair.com; Website: haiphongshiprepair.com

NON DESTRUCTIVE TESTING

PLEASED CONTACT US TO GET NDT FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : 0084904125520; Email: bacviet@haiphongshiprepair.com

Ultrasonic Testing (UT)

Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. Ultrasonic inspection can be used for flaw detection/evaluation, dimensional measurements, material characterization, and more. To illustrate the general inspection principle, a typical pulse/echo inspection configuration as illustrated below will be used.

A typical UT inspection system consists of several functional units, such as the pulser/receiver, transducer, and display devices. A pulser/receiver is an electronic device that can produce high voltage electrical pulses. Driven by the pulser, the transducer generates high frequency ultrasonic energy. The sound energy is introduced and propagates through the materials in the form of waves. When there is a discontinuity (such as a crack) in the wave path, part of the energy will be reflected back from the flaw surface. The reflected wave signal is transformed into an electrical signal by the transducer and is displayed on a screen. In the applet below, the reflected signal strength is displayed versus the time from signal generation to when a echo was received. Signal travel time can be directly related to the distance that the signal traveled. From the signal, information about the reflector location, size, orientation and other features can sometimes be gained.

Ultrasonic Inspection is a very useful and versatile NDT method. Some of the advantages of ultrasonic inspection that are often cited include:

+ It is sensitive to both surface and subsurface discontinuities.

+ The depth of penetration for flaw detection or measurement is superior to other NDT methods.

+ Only single-sided access is needed when the pulse-echo technique is used.

+ It is highly accurate in determining reflector position and estimating size and shape.

+ Minimal part preparation is required.

+ Electronic equipment provides instantaneous results.

+ Detailed images can be produced with automated systems.

+ It has other uses, such as thickness measurement, in addition to flaw detection.

As with all NDT methods, ultrasonic inspection also has its limitations, which include:

+ Surface must be accessible to transmit ultrasound.

+ It normally requires a coupling medium to promote the transfer of sound energy into the test specimen.

+ Materials that are rough, irregular in shape, very small, exceptionally thin or not homogeneous are difficult to inspect.

+ Cast iron and other coarse grained materials are difficult to inspect due to low sound transmission and high signal noise.

+ Linear defects oriented parallel to the sound beam may go undetected.

+ Reference standards are required for both equipment calibration and the characterization of flaws.

Magnetic Particle Testing - (MT)

Magnetic particle inspection (MPI) is used for the detection of surface and near-surface flaws in ferromagnetic materials. A magnetic field is applied to the specimen, either locally or overall, using a permanent magnet, electromagnet, flexible cables or hand-held prods. If the material is sound, most of the magnetic flux is concentrated below the material's surface. However, if a flaw is present, such that it interacts with the magnetic field, the flux is distorted locally and 'leaks' from the surface of the specimen in the region of the flaw. Fine magnetic particles, applied to the surface of the specimen, are attracted to the area of flux leakage, creating a visible indication of the flaw.

The materials commonly used for this purpose are black iron particles and red or yellow iron oxides. In some cases, the iron particles are coated with a fluorescent material enabling them to be viewed under a UV lamp in darkened conditions.

Penetration Testing - (PT)

Much of the confusion surrounding penetration testing stems from the fact it is a relatively recent and rapidly evolving field. Additionally, many organisations will have their own internal terminology (one man's penetration test is another's vulnerability audit or technical risk assessment).

At its simplest, a penetration-test (actually, we prefer the term security assessment) is the process of actively evaluating your information security measures. Note the emphasis on 'active' assessment; the information systems will be tested to find any security issues, as opposed to a solely theoretical or paper-based audit.

The results of the assessment will then be documented in a report, which should be presented at a debriefing session, where questions can be answered and corrective strategies can be freely discussed.

RECONDITION PISTON CROWN IN VIETNAM AND EXHAUST VALVES

PLEASED CONTACT US TO RECONDITION PISTON CROWN FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : +84 904 125 520; Email: bacviet@haiphongshiprepair.com

Bacviet Commercial and Shiptech is leading Company in Vietnam for recondition Piston Crown,Exhaust Valve and Valve seat of Marine Engines.

With many experieces in this field, good skilled engineers and new model equipments for recondition Engine Piston Crown, Exhaust valves, Valve seat and Spindle in the Ports of Vietnam or at Vietnam Anchorage.

_600x800.jpg)

The works to be carried out as following item:

- Preliminary inspection - checking of fundamental dimension

- Roughing out

- NDT inspection for possible cracks or defect

- Complete rebuilding of groove and diameter by welding up with special welding rod

- Checking of piston top surface deposited layer

- Machined of contact faces and inner diameters

- Roughing out .

- Finishing of piston crown top surface

- Machined of new grooves

- Clean for checking

- Checking of grooves' width and depth

- Checking of piston diameter and height

- Grinding and polishing

- Diameter measurement

PLEASE CONTACT US TO RECEIVE UNDERWATER SERVICES FOR YOUR GOOD VESSEL IN VIETNAM AS FOLLOWING:

Mobile Phone, WhatsApp, Wechart, Zalo : 0084904125520; Email: bacviet@haiphongshiprepair.com

With many experieces in this field, good skilled technicals and quick team mobilization, we provide underwater hull cleaning/ underwater inspection or underwater work in all ports and anchorage of Vietnam.

1/ UWC - Underwater cleaning ship hull in Vietnam to be used new model equipments as: Brush -Kart, Hydroblast Jet to avoid any damage of antifouling coating for Vertical Bottom sides and Flat Bottom. Underwater cleaning for ship also carries out for Bilge Keel, Sea chest gates, Propeller blades and Hub, Rudder ...etc. After cleaning, CCTV to be carried out for final check condition of shiphull and also to known well the condition of the bottom plugs, speed log, echo sounder, propeller cutter rope, overboard holes.

Polishing Propeller blades also carries out by special equipments and Rubet scan for reference.

At present time, with new model equipments - speed for cleaning ship hull is too fast and safety.

Finaly: A hull after cleaning will be reduced fuel consumption by 6% up to 20% and lower emission significatly.

2/ At present time, we use ROV ( Remotly Opperate Vehicle) for underwater inspection Ship hull with Class BV, NK, ABS and DNV LR approved.

We can provide services such us:

- Underwater hull inspection UWI

- Underwater inspection lieu dock UWILD Class survey

- Underwater hull cleaning

- Underwater Anodes installing

- Underwater Sealing of leakage

- Underwater cofferdam installation

- Underwater blanking and plugging

- Underwater polishing propeller

- Underwater cutting rope

- Underwater repair propeller blade damage.

- Underwater welding

- Hotline: +84 904 125520

- bacviet@haiphongshiprepair.com

PROJECTS UPDATE

- MAIN ENGINE WinGD 6X82-2.0 REPLACE CYLINDER LINER IN HAIPHONG VIETNAM Updated: 2025-04-21

- REPAIR ALUMINUM HYDRAULIC COOLER FOR SHIP CRANE IN VIETNAM Updated: 2025-04-21

- REPAIR HYDRAULIC CYLINDER FOR LIFEBOAT DAVIT OF MV JABAL SAMHAN IN PHU MY PORT, VIETNAM Updated: 2024-05-31

- WINDLASS, MOORING WINCH REPAIR IN VIETNAM Updated: 2024-04-23

VIDEO

- BAC VIET SHIPREPAIR COMPANY IN VIETNAM - INTRODUCE

- UNDERWATER HULL CLEANING BY ROV

- UNDERWATER SURVEY BY ROV IN VIETNAM

- LOAD TEST CONTAINER FLAT RACK IN VIETNAM

- CRANE JIB REPAIRS IN VIETNAM

- REPAIR PROPELLER IN VIETNAM

- STEEL REPAIRS IN VIETNAM

- STEEL REPAIRS IN VIETNAM

- TURBOCHARGER OVERHAULING IN VIETNAM

- STEEL REPAIRS IN VIETNAM

- REPAIR PROPELLER IN VIETNAM

- REWINDING GENERATOR, ELECTRIC MOTOR IN VIETNAM

- OVERHAUL MAIN ENGINE IN VIETNAM

- REPAIR CELL GUIDE IN VIETNAM

- REPAIR ALUMINUM ACCOMMODATION LADDER IN VIETNAM

- REPAIR JIB CRANE IN VIETNAM

- REPAIR JIB CRANE SHEAVE IN VIETNAM

- STEEL REPAIR FOR VESSEL IN VIETNAM

- LOAD TEST CRANE IN VIETNAM

- REPAIR ALUMINUM GANGWAY IN VIETNAM

- REPAIR ALUMINUM HYDRAULIC COOLER OF CRANE IN VIETNAM

- SHIP BRIDGE MAST MODIFICATION